- Week 1

- Week 2

- Week 3

- Week 4

- Week 5

- Week 6

- Week 7

- Week 8

- Day 30

- Day 31

- Day 32

- Week 9

- Week 10

- Week 11

- Week 12

- Week 13

- Week 14

- Week 15

- Week 16

- Week 17

- Week 18

- Week 19

- Week 20

- Week 21

- Week 22

- Week 23

- Week 24

The Which Kit Car? top threeYesterday, I received my copy of Which Kit Car? where they'd had the Aeon as one of the three finalists for the kit car of the year. While it excelled on handling and performance, the main things it failed on was the styling and build quality. There isn't a lot I can do with my car with the styling (unless I get into a lot of GRP modifications), but there are some aspects of the build quality I can certainly improve on. One of the things that they picked up on (and I've already noted) was that the doors are wobbly. So, today I had a closer look at the hinges that I was planning on using. There is a fair amount of play in them - however, there are better hinges that can be made... New hingesI sketched the design for the hinge on a piece of cardboard. The design behind this is similar to one I used on the front of my Karma (although on this, the bonnet was too heavy and it was stressing the front a lot - so I dropped this design). The idea is to move the central pivot behind the join between the two panels. I had some 88mm diameter pipe I bought some time ago but hadn't used - cut this in half, and I've got two hinges. First of all, I cut it into a 100mm length, and then split it into two: I then got some 14mm diameter pipe (with a 1mm wall thickness) which would allow me to put a long 12mm bolt through it. This was welded to a flat bar to move the 14mm pipe to the centre of the hinge.

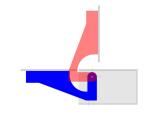

This was then joined to the half-circle. Unfortunately, I made one slight miscalculation - as I'd bonded the body to the chassis, I couldn't drill the hole for the 12mm bolt through the door hinge section. However, I could put a bolt in from either end. This hinge was fine as a rough design, but a neater solution is required. The shape of the hinge section really requires the use of a tool I do not have to make - a plasma cutter. Luckily, my mate, Pete, has one, so I'll do some designs to come up with a template to make one out of. Hinge designHere's a side-view design of the hinge I need to make. It could be made with an angle grinder - although the curve would need a lot of nibbling bits away.

The shaded area to the right is the inside of the cavity already present (which is 100mm x 60mm from the front - the depth along the body does not make that much of a difference). The blue is the basic design, shown at 0°, whilst the pink is the same, but at 90°. And here's a 6M MPEG1 video of it opening/closing that I quickly did using Lightwave Light green is used to indicate the GRP (it's semi-transparent), and yellow is the cut-out section for the normal hinge (it's also semi-transparent). The gas spring will have to be mounted in front of the cut out section (otherwise it'll interfere with the top GRP). |

Copyright © 2005-2007 Tribbeck.com / Jason Tribbeck